The past and future meet – the old 737 livery on the stairs and the the MAX’s new livery on the jet

This week, Boeing took the time to not only show off their improved production line for the 737 MAX, but also the first (and second) aircraft. Over two days, AirlineReporter visited Boeing’s 737’s factory in Renton, Wa to learn more about the 737 MAX and how Boeing will go about producing them.

The MAX is the fourth generation of the venerable 737 and will replace the 737 Next Generation (or 737 NG). The first 737 first flew in April 1967 and, although it might have the same name and a similar appearance, the aircraft has changed dramatically over the years.

The MAX will come in three main flavors: the MAX 7, MAX 8, and (wait for it) MAX 9. I have to say that it’s a bit weird to have the “MAX” [aka maximum] with a 7, but then also an 8 and 9? Oh well.

Boeing’s new Advanced Technology winglets are a distinctive feature of the 737 MAX.

The number of passengers in each respective version of the aircraft will be similar to the 737 NGs. The MAX 7 will carry 126 to 149 passengers, the MAX 8 will carry 162 to 200 (with the MAX 200 for Ryanair), and the MAX 9 will have 180 to 220. These changes are taking the 737 frame, technology, and cost savings… well… to the MAX!

The money shot: 747 line inside the Boeing factory

Back in the 1960s Boeing made a big gamble. They decided to build the world’s largest airliner, the Boeing 747 Jumbo Jet. To build such a beast, they would need a large facility. After careful consideration, Boeing decided to build a large factory in Everett.

Since the first 747 rolled off the line in 1968, every other 747 has been built under the same roof. Even today, the 747-8 is built in the same factory.

In case you didn’t know the aircraft type, there is a large sign on the wall.

Although Boeing offers public tours of the facility, they do not allow cameras. I was lucky enough to participate in a media event and take photos of the 747 line in the factory and I wanted to be able to share. Enjoy…

A group of AvGeeks in front of a Boeing 747-8I – Photo: The Boeing Company

What a ride! This year’s Aviation Geek Fest Seattle was bigger and better than ever.

I have to say that I am very honored by the fact that I get flown around the world to do some pretty amazing aviation-related things, but Aviation Geek Fest has become one of my favorites to look forward to each year. I am just so happy I got to share the experience with 300 AvGeeks!

Boeing SST mockup in the Museum of Flight Restoration Center

SATURDAY: PAINE FIELD DAY

For me, the first day (Saturday the 15th) started with a trip to the Museum of Flight Restoration Center where I was able to check out the Boeing SST mockup, a Comet, the first-ever Boeing 727, and a Boeing 247.

BONUS: An Inside Look How the Museum of Flight Restores Their Aircraft

I just love the feel of this facility; it is raw. Although there were many cool ongoing projects, the best part was talking to the folks doing the restoration. They love what they do, they have a sense of humor, and they have so much amazing background on the planes.

American Airline’s sixth Boeing 777-300ER, sitting at Boeing Field. Photo by Brandon Farris.

I recently had the opportunity to hang out with American Airlines while the carrier and Boeing enjoyed some festivities prior to the airline taking delivery of its sixth 777-300ER (77W) on April 11th.

Everything began early in the morning with a short drive from the Crowne Plaza Hotel in downtown Seattle to Renton, home of the Boeing 737 final assembly lines. Although we were set to fly the 777, American had recently placed a large order for the 737 NG and MAX.

A model of the Boeing 787 outside the Visitor Center in South Carolina. Check out the wing-like roof.

This is a guest post written by Drew Vane for AirlineReporter.com:

I recently visited a Boeing Factory. No, I’m not talking about Renton or Everett, but in South Carolina.

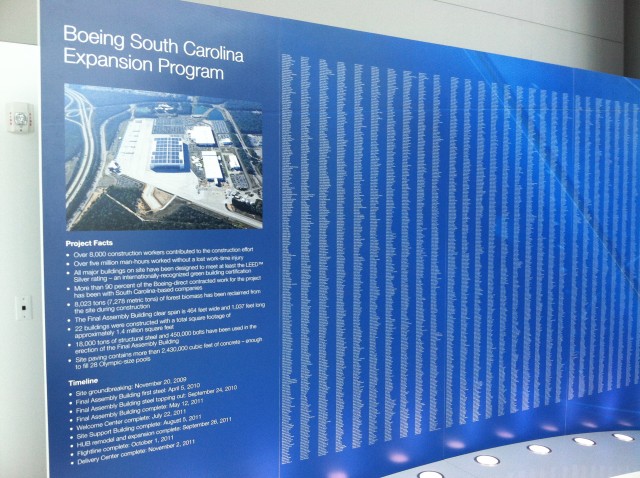

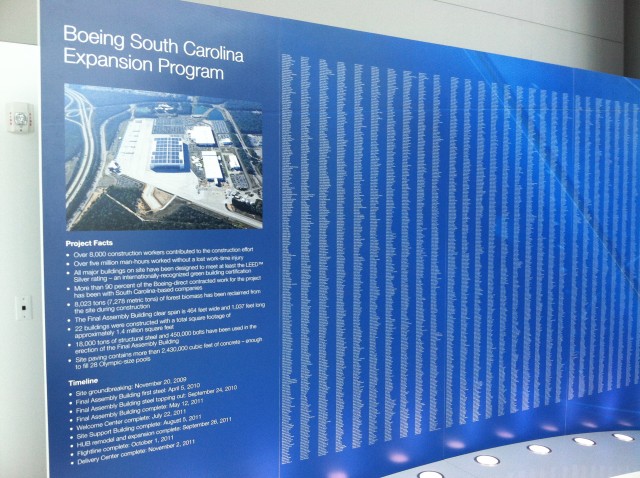

Covering almost 11 football fields and completed in mid 2011, Boeing’s ’œother’ factory for manufacturing the new 787 Dreamliner is located in North Charleston, South Carolina on property bordering Charleston International Airport and Joint Base Charleston. I had the opportunity to stop by during a business trip recently and let me tell you, this facility is impressive. According to Boeing’s web site, ’œBoeing South Carolina fabricates, assembles and installs systems for aft (rear) fuselage sections of the 787 Dreamliner and joins and integrates mid-body sections from other partners.’

These partners include companies located in India and Japan. While I wasn’t able to tour the facility during my trip, I did take a short visit to the visitor’s facility and grabbed some pics of the lineup near the fence line. I just happened to miss the second 787 Dreamliner to depart for India by only one day. I also missed the departure of the Dreamlifter with its precious cargo bound for Seattle, but I hope to catch one in the future.

Some 787s on the tarmac at Boeing’s South Carolina facility. Image by Drew Vane.

Since green is the name of the game these days, Boeing designed this facility to be as environmentally friendly as possible. The final assembly building was fitted with solar panels that are capable of generating enough electricity to power 250 homes with a peak energy output equal to 200,000 13-watt watt bulbs. In addition, Boeing has a zero waste program where recycling and reuse is the norm, creating zero waste to landfills from the facility as a whole. Quite impressive for such a large manufacturing facility.

The visitor’s center unfortunately is for those with permission to enter the site. I had hoped to see a retail store, room full of Boeing paraphernalia and models for sale. It is too bad that the store is behind the fence, far from public eyes. The visitor center is more a front gate for those seeking security badges or meeting Boeing employees. They did have a very nice facility with a roof in the form of a 400-ft long wing, an outside small display with the history of Boeing, and a large scale model of the 787.

Boeing workers who built the facility

A very courteous Boeing employee was kind enough to talk with me as he was leaving for the day. Boeing’s Charleston facility is the only location currently in the world where the 787 tail assembly is manufactured. Boeing ships the tails to Everett where they’re assembled. Similar to Everett, all the parts are shipped here to Charleston for assembly. At the present time, Boeing’s manufacturing is only capable of producing one 787 per month. But, they hope to eventually ramp that up to one every six days, similar to the Everett Washington facility.

From public areas, I did spot some red tails (not the movie) in the lineup area and took a drive over, stopping outside the fence to snap a pic of the lineup. What an impressive sight! I was excited just to be in the same state as these fine aircraft. I cannot wait until my next visit.