-

-

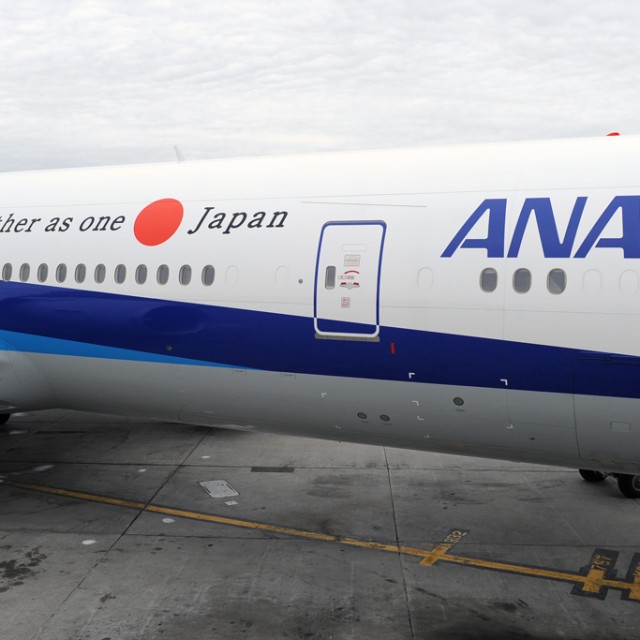

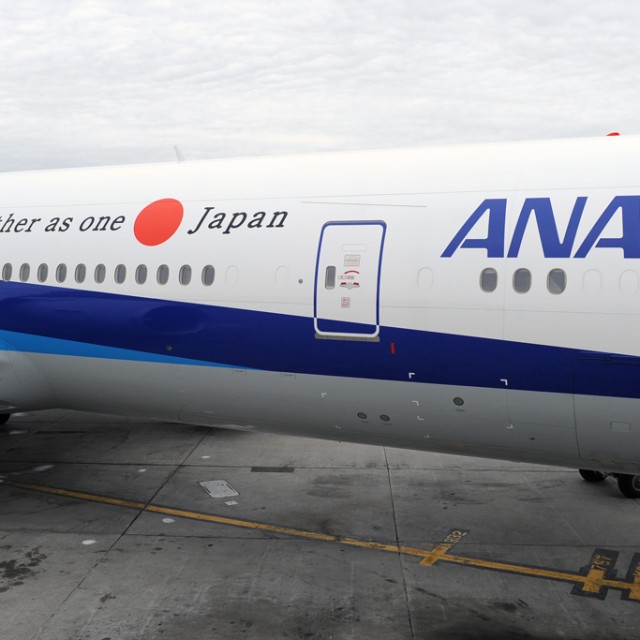

From the JFK tarmac: ANA Boeing 777-300ER (JA786A). Manny Gonzalez / NYCAviation

-

-

The updated livery up close. Manny Gonzalez / NYCAviation

-

-

ANA Boeing 777-300ER (JA786A) with updated livery. Manny Gonzalez / NYCAviation

-

-

ANA Boeing 777-300ER (JA786A) with special Japan Relief livery at JFK. Manny Gonzalez / NYCAviation

Click any image above for larger version

All Nippon Airways (ANA) announced a special livery that supports the recovery effort in Japan. Last week, one of their Boeing 767-300ERs (JA611A) showed off the special “Forward together as one, Japan” livery.

On May 2nd, ANA displayed a Boeing 777-300ER (JA786A) with the relief-related message at New York’s John F Kennedy Airport (JFK) for photographers and invited media.

“ANA wishes not only to support those who have been affected by the earthquake, but also move forward together with them to rebuild the region,” ANA spokes person told Airline Reporter. “For our global passengers, ANA would like to reassure our commitment to safety and top quality services through this message as well.”

As of March 13th, all ANA international flights have been operating on their normal schedule. Since April 13th, ANA has been back to flying to all the domestic airports it regularly serves as well as additional relief flights to Senai and Yamagata.

ANA is not sure how long the special livery will fly on the aircraft, but it will be at least through the month of May. NYCAviation has all 13 photos taken by Manny Gonzalez.

This story was a joint effort between AirlineReporter.com and NYCAviation.com

Boeing 787 Dreamliner for ANA in Boeing's factory. Photo by AirlineReporter.com.

Yesterday, I took a look how All Nippon Airways (ANA) and Boeing have worked together to prepare and train for the Boeing 787 Dreamliner. Today, we will explore how ANA directed some of the 787’s development and how their relationship with Boeing and other vendors will continue after they take delivery of the first Dreamliner.

ALL NIPPON AIRWAY’S INPUT

A large benefit of being the launch customer is that the airline gets to have influence over the development of the aircraft. ANA has been able to have a positive impact on the development of the 787 and Boeing has welcomed their input. Finding out how to make the 787 Dreamliner the best plane possible became a team effort. ANA reached out to employees throughout the company to determine what they would like to see in the new plane.

“ANA is much more than a customer for the 787 program. ANA has been a partner in helping us to make important decisions and in understanding our challenges and the solutions that have been developed,’ Scott Fancher, Vice President and General Manager of the 787 Program stated.

On many other aircraft, the front cockpit windows will open, allowing the crew to clean them if needed. The Dreamliner did not have opening windows, so ANA worked with Boeing to develop a window washer system, like you might find on a car that performs that function. ANA has also requested that Boeing develop oxygen masks that would better fit to the shape of Asian face.

EROS which is the manufacturer of the oxygen masks reviewed the data base to fit the various racial faces.

Most of the ideas proposed by ANA have been accepted by Boeing. ’œDuring our discussions, Boeing understood ANA’s requests,’ Mr. Kikuchi explained. ’œAlmost 70% of our unique requests have been implemented on the airplane.’

POST DREAMLINER DELIVERY

According to the most recent buzz, the first 787 Dreamliner is scheduled to be delivered to ANA as early as July 2011. Flight Global reports that the eighth 787 (ZA101) is currently set to be the first aircraft delivered to ANA, configured in a two-class, medium to short-haul set up. According to Boeing, they are not planning to sell the first three test planes, but do plan to sell the rest of the Dreamliners currently being used for testing.

Once Boeing hands over the keys of the first Dreamliner to ANA, the airline and aircraft manufacture will still have a very close relationship in continuing to assist with the development of the 787. For the first three months of ownership, Mr Kikuchi explained that Boeing and other vendors will support ANA strongly.

’œWe are working hard to finish our remaining requirements and look forward to a grand celebration of our first delivery with our good friends from ANA later this year,’ Boeing’s Fancher said. ’œThat delivery will be the first of many and each will be an opportunity to work together and celebrate our mutual accomplishments.”

Boeing 787 Dreamliner ZA002 flying high with ANA livery. Photo by Boeing.

CONCLUSION

ANA is very pleased to be the first customer for the 787 and it shows. Much of their marketing has the Dreamliner prominently displayed and even their business cards have ’œ787, We Fly 1st’ printed on them.

All Nippon Airways already has a large presence with over 180 aircraft and over 70 destinations world-wide. They have flown many different types of aircraft since being founded in 1952; from DC-3s to Boeing 727s, they are no stranger to different aircraft types.

The Dreamliner will allow them to be the first to fly the next generation airliner and for many that is a very exciting prospect. It has to be even more exciting for the employees of ANA to know they have had such a direct impact with the 787’s development and that is something to be very proud of.

Talking to ANA About the 787 Dreamliner:

PART 1 | PART 2 | BOTH

Boeing 787 Dreamliner in ANA livery at Everett Field. Photo by Boeing.

INTRODUCTION

Although the Boeing 787 Dreamliner looks similar to previous aircraft, it uses the next generation of technology and materials. Designing, building and then training for such a complex aircraft is no easy task. How does an airline go about preparing to take delivery of a brand new aircraft?

All Nippon Airways (ANA) will be the first airline to take delivery of the 787 and I recently had the opportunity to sit down with Mr. Takeo Kikuchi, ANA’s General Manager of the USA Engineering Office, and with Nao Gunji, ANA’s Communications Coordinator, to learn more about how they are preparing for the Dreamliner.

Today this story will give some background on the Dreamliner and the training that ANA has completed for the 787. Tomorrow, I will post about ANA’s input on developing the 787 and what happens after they take delivery.

I felt honored to have the opportunity to speak with Mr. Kikuchi. He started working in the airline business in 1980 as a mechanic and did heavy maintenance on classic Boeing 747s in Japan. Subsequently he was responsible for overseeing hydraulic systems on, allowing him to expand his engineering experience. He then worked in public relations for about three years before moving to Seattle in 2007 to lead the local ANA engineering office at Boeing.

Mr. Kikuchi’s main responsibility is to communicate to Boeing the needs of his airline and ensure ANA receives the best quality plane possible. ’œANA’s drive is to purchase a reliable, convenient and usable airplane,’ he explained.

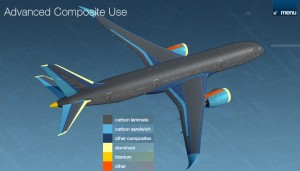

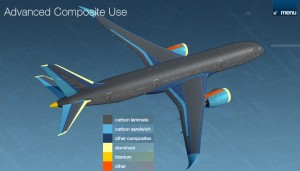

Graphic showing the different materials used in the Boeing 787 Dreamliner. From Boeing.com.

787 AIRCRAFT MATERIALS

The type of materials used is one way the 787 is unique from other aircraft (what makes the 787 different). Currently most aircraft are built using large aluminum panels and are riveted to a metal frame. In contrast, the 787 is constructed using large sections of mostly carbon composite materials that do not need to be riveted. Although the new material makes for a stronger and lighter aircraft, it can provide some challenges.

One of those challenges is how to repair the aircraft. To repair an aluminum aircraft, ANA puts a temporary patch on the affected area and then flies the damaged plane to their maintenance facility in Japan for a permanent repair. With carbon fiber, it is not as easy and will be more difficult to complete a temporary repair before flying to a repair facility. ANA is currently working with Boeing on perfecting the best way to make short-term repairs to the Dreamliner.

One advantage of a carbon fiber repair is the long term benefits. With an aluminum repair, an airplane will have additional squares of aluminum riveted onto the fuselage, causing additional weight and lowering aerodynamics ’“ raising fuel costs. After 787 composite repairs, the change of the aircraft weight and aerodynamics will be minimal, saving money over the lifetime of the airframe.

Japanese reporters getting a look at one of the two 787 full flight simulators in action at the Boeing/ANA training campus in Tokyo on March 7. Photo by Boeing.

ANA TRAINING

Although there are many forms of training, nothing beats hands-on experience. Mechanics have started with computerized training, but at some point will be flown from Japan to Paine Field in Everett, WA where the Dreamliner is built. To date, there have been over 100 ANA mechanics, who visit in groups of 10-12, who have been flown to Seattle to train on the Boeing 787 Dreamliner.

Even though there have been ANA pilots who have flown the Dreamliner, not all the pilots will have that chance before the airline takes delivery. The Japanese Civil Aviation Bureau (JCAB) approved Dreamliner simulators at the ANA/Boeing training campus in December 2010. ANA will start 787 pilot training as early as this month.

ANA has invested a lot of time, money and their future into the Boeing 787 Dreamliner and Boeing knows how important their relationship with ANA is. “I can’t say enough about Boeing’s special relationship on 787 crew training with ANA over the past four-plus years, ’ Sherry Carbary Vice President, Flight Services, Boeing Commercial Airplanes said. ’œTheir attention to detail was outstanding and made us better for it.’

After speaking with Mr. Kikuchi, I had a quick tour of the Boeing factory and the 787 production line (sorry, no photos). Now, I am no stranger to the factory, but this was much different tour being that I was guided by an airline representative and hearing their perspective.

While getting a tour of one of their 787 Dreamliners in production, we saw a group of ANA mechanics getting a quick look at the aircraft. Mr. Kikuchi told us that the mechanics would be given a scenario concerning a problem and they would learn how to solve it. It is one thing to talk about the 787 in a conference room versus being out with on the aircraft and seeing the mechanics in action.

Talking to ANA About the 787 Dreamliner:

PART 1 | PART 2 | BOTH

The 1000th Boeing 767 (JA622A) looked gorgeous in her newly painted ANA livery.

Yesterday was quite the milestone for Boeing. About three weeks ago, Boeing invited folks to check out the 1000th Boeing 767 during final assembly. It was a small gathering of people to remember how much the 767 has done for the airline community and looking forward to a possible tanker deal. Yesterday’s event was quite a bit larger and really felt more like a celebration.

Even though the 1000th 767, in All Nippon Airways (ANA) livery, was center stage, the ceremony really honored the past, present and future of workers who have had an impact on the 767. Bus loads of retired Boeing employees, who at one time or another worked on the 767 line, were taken to the factory floor and as the ceremony progressed, current Boeing employees gathered from all around the factory to join in on the event. We were all treated to multiple professional videos showcasing the 767’s past and there was even a 767 song that was surprisingly catchy (trying to work on getting a copy of that still).

This also gave an opportunity to look at the recent 767 production line reconfigurations. While fancy lights shined on the 1000th 767, the much less popular 1001st Boeing 767 looked on. Even though it didn’t get the attention it deserves, the 1001st aircraft will be the first to actually roll off the new 767 line. To create the new line, 8000 yards of concrete were removed, a building was partly cutdown, a new hangar door was installed and 767 tooling was moved around. It was quite the change and leaves the 767 a pathway from the rear of the factory to the front with just five feet of clearance in some areas.

During the event, Jim Albaugh, President and CEO of Boeing Commercial Airplanes, stated he was confident that the Boeing 767 would have a long life ahead of it, even if the tanker deal does not go through. “The 767 is still a very, very efficient airplane. In fact, from a trip standpoint, it’s the most-efficient twin-aisle airplane being manufactured (it’s also the smallest).” Albaugh continued, “And we have quite a number of customers we’re talking to right now about buying this airplane for commercial use. And I think we’ll be here, I hope, in another few years to be talking about the delivery of airplane 2,000.”

After the mood lights and crowd were gone, the 767 (JA622A) still looked beautiful.

This is not to say that Boeing doesn’t have every confidence that the 767 tanker will be chosen. “It’s the best airplane,” Albaugh said. “It’s an airplane that can put more booms in the sky. It’s an airplane that’s much more efficient to operate. It’s an airplane that can forward deploy to all the fields that the Air Force needs it to go to.”

After the ceremony, when Albaugh was asked how the older Boeing 767 will be able to effectively compete with the Airbus A330, he stated that the demand for wide body aircraft will be too great and with recent cost reductions in the aircraft, the 767 can will be a viable competitor. “We have figured out a way to take a lot of cost out of this airplane. And I think now that we’ve worked through that we’re going to have a very competitive offering going forward.” He also talked about the A320neo, the 777 replacement and outsourcing lessons learned on the 787. It’s all good information, but since Aubrey Cohen with the Seattle PI covered those parts so well, I don’t want to re-hash here.

Boeing has put a lot of time and money on the line for the future of the 767. I might not have the positive outlook for the 767’s future, if the tanker deal doesn’t go through, but I would imagine Boeing has looked how to convert the 767 line to produce 787’s if needed. Let’s hope one way or another it all pays off.

MORE GOODIES:

Of course you need more eye candy: here are 28 photos of the 1000th 767 event and a video from Boeing showcasing three generations on the 767.

It is interesting (at least to me) to see the different headlines that come from people attending the same event. I find it sort of refreshing. Here are some examples (all good reads btw):

* Boeing’s new 767 line ready to make Air Force tankers by Aubrey Cohen at Seattle PI

* Boeing rolls out 1,000th 767, but all eyes still on tanker deal by Glenn Farley at KING5

* Temporary 787 line in Everett could become more permanent by Michelle Dunlop with The Everett Herald

* Albaugh says Boeing’s 767 can still find customers by Dominic Gates with the Seattle Times

* Boeing Celebrates Completion of 1,000th 767 Jet by NYCAviation

Boeing's 1000th 767 (JA622A) that is in the final assembly stage in the Boeing Factory.

Making just one aircraft is pretty darn impressive. Making 100 isn’t too shabby. But you know you have made it as an airliner if there have been a 1000 of your kind made. Although Boeing has made over 6600 Boeing 737’s, making 1000 767’s is nothing to sneeze at (wow, it would suck to be allergic to airplanes).

The 767 and 757 were designed together and were as close to siblings as airliners can get. They both have similar flight decks and handling abilities so that pilots could easily be cross-trained. The 767 was the first wide-bodied, twin-engine airliner that Boeing made and the first wide-bodied airliner to go to a 2-person flight deck crew. The first Boeing 767 took flight on September 26, 1981 and entered service with United airlines about a year later in September 1982. Since then the airplane has served many airlines well, but it might have always been a little jealous of its skinnier and more popular sibling, the 757.

When the last Boeing 757 was built in October 2004, there had been 1050 buit. For a while it seemed like the 757 would have been the more successful sister of the two aircraft as sales of the 767 have declined greatly over the past few years.

The 1000th Boeing 767 (JA622A) still have about a month til she will be delivered to ANA.

Currently, Boeing has delivered 995 Boeing 767’s and have another 50 on order. That means if the tanker deal doesn’t go through and no more aircraft are ordered, the 757 will go down in history with more aircraft built: 1050 vs 1045.

The Boeing 767 has remained in production for two major reasons: making it the next generation of military tanker and the Boeing 787 Dreamliner delays. Many airlines, including All Nippon Airways (ANA), were counting on the 787 Dreamliner to be completed long ago. Boeing has worked with airlines to provide them with temporary Boeing 767-300ER’s. “A couple years ago we started having discussions about providing 767s on an interim basis to some Dreamliner buyers as well as other carriers looking for twin-aisle planes. We saw interest from all regions for both passenger airplanes and freighters,” Leslie Hazzard with Boeing 767 Communications explained to me.

Although Boeing does say they have made deals with airlines, they aren’t willing to speak financial specifics, “We don’t discuss the financing terms that were considered, but at the time we said publicly that any deal would involve long-term commitments and need to make good business sense for both the airlines needing the lift and for the Boeing organizations involved,” Hazzard stated.

So, why bring up the 1000th Boeing 767 again? On Monday Boeing invited a few folks out to take a look at the final assembly of the 1000th 767, which will have registration number JA622A. ANA hopes to take ownership of the aircraft sometime during the third or fourth week of February. The special 1000th 767 event was pretty interesting. Boeing executives spoke at a podium next to the plane and workers from around the factory started to gather around and listen. Once the event was done, the workers went right back to getting the 1000th 767 ready to fly.

Right now, Boeing is storing three 787 Dreamliners on the current 767 line. There were two ANA 787’s (one in white livery, another in full livery) and one Air India. Unfortunately we weren’t able to take photos of the 787 at that time, but it was very cool seeing how different the ANA Boeing 787 Dreamliner parked right next to an ANA Boeing 767. The 767 is a wonderful aircraft that has served the world well and hopefully will continue to do so, but seeing it next to the 787, it is obvious that the Dreamliner is the next generation of airliner.

CHECK THIS STUFF OUT:

* 23 photos of the 1000th Boeing 767

* Story and video from Glenn Farley at KING5

* Story and photos from Aubrey Cohen at the Seattle PI

* Story from Michelle Dunlop on the Everett Herald